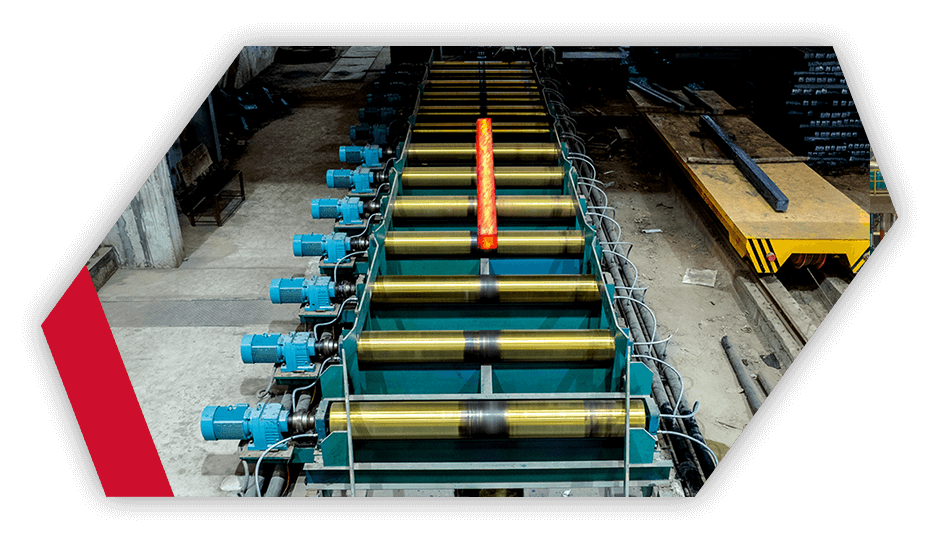

Rolling Section

AUTOMATED FOR CONSISTENCY AND OPTIMIZATION

Our state-of-the-art Induction Furnaces are built with higher turbulence settings to avoid any infiltration of non-metallic impurities in molten steel. These turbulence settings separate the impurities and slag, which are later removed from the pure metallic melt, ensuring only the purest mix is left for making steel billets.

PERFECT CURVATURE & EVEN WEIGHT DISTRIBUTION

Consistent weight distribution throughout the length of the rebars makes for true international quality steel. We have equipped our rolling mill with 8 Loopers for giving better curvature and weight distribution to our rebars. Our rebars are flawless in shape and uniform in weight from one end to another – making them perfect deformed bars (i.e. rebars with visible ribs) - but not distorted or disfigured in any way.