IMPURITY ISOLATION

Our state-of-the-art Induction Furnaces are built with higher turbulence settings to avoid any contamination of non-metallic impurities in molten steel. These turbulence settings separate the impurities and slag, which are later removed from the pure metallic melt, ensuring only the purest mix is left for making steel billets.

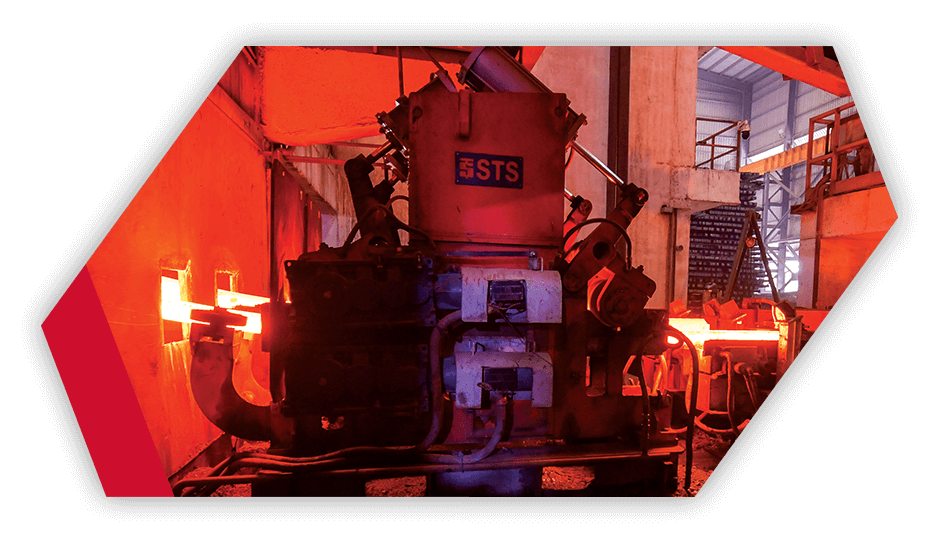

EUROPEAN CONTINUOUS CASTING MACHINE

Pakistan’s first and only European, high-speed CCM having 7/13 radius. This ratio gives better stress handling while casting, a characteristic which is passed on to rebars produced with our billets. Our Italian CCM also uses quality Copper Mould Tubes for premium surface finish of steel billets with less scaling on billets/rebars.